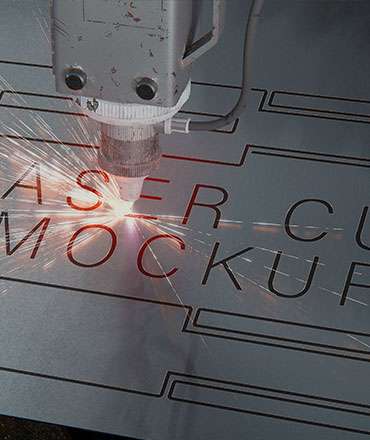

We specialize in precision laser and plasma cutting for a wide range of materials, ensuring exceptional accuracy and efficiency in all our projects. Whether you need intricate designs or rapid metal cutting, our expert team is here to deliver top-notch results for your industrial, artistic, or manufacturing needs.

Request for QuoteServices - Cenad Art

- Home

- Services

Quality Manufacturing is Our Objective

Laser cutting is a precise and versatile manufacturing process that uses a high-powered laser beam to cut through various materials with ...

Laser engraving is a non-contact, permanent marking technique that uses a focused laser beam to etch or engrave designs onto various ...

Laser marking is a non-contact, permanent marking process that uses lasers to create high-quality, permanent marks on a wide range of ...

Elevate your creations with precision and artistry through our etching service, adding enduring elegance to various materials.

Engraving service provides custom and personalized solutions to etch, carve, or mark various items, adding sentimental value, aesthetic appeal, or identification ...

Unlock the power of vivid expression with our expert printing service, turning your ideas into striking reality.

Manufacturing Processes

Request Quotation

The first step in any cutting process is selecting the appropriate material to be cut. Different materials have varying properties and characteristics, such as hardness, thickness, and conductivity, which can influence the choice of cutting method and equipment.

Preparing the Workpiece

Before cutting, the workpiece must be properly prepared to ensure accurate and efficient cutting. This may involve cleaning the surface, marking the cutting lines, and securing the material in place to prevent movement during the cutting process.

Cutting Technique Selection

Depending on the material, thickness, and desired precision, the most suitable cutting technique is chosen. Laser cutting is ideal for intricate designs and fine detailing, while plasma cutting excels in rapid metal cutting, particularly for thick materials.

Post-Cutting Finishing

After the cutting process is completed, the workpiece may require additional finishing, such as deburring, polishing, or coating, to achieve the desired final appearance and functionality.

-

01

Request Quotation

-

02

Preparing the Workpiece

-

03

Cutting Technique Selection

-

04

Post Cutting Finishing